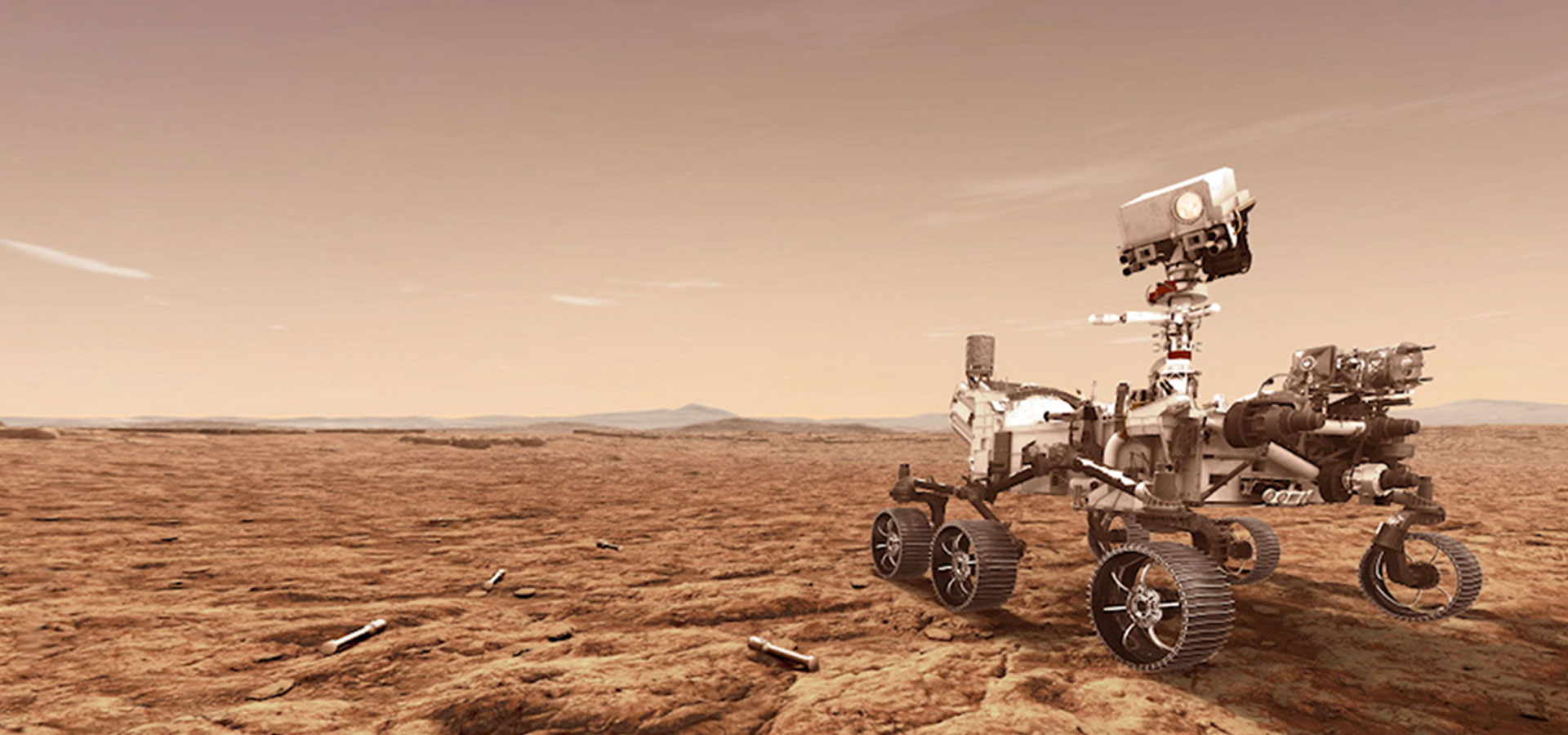

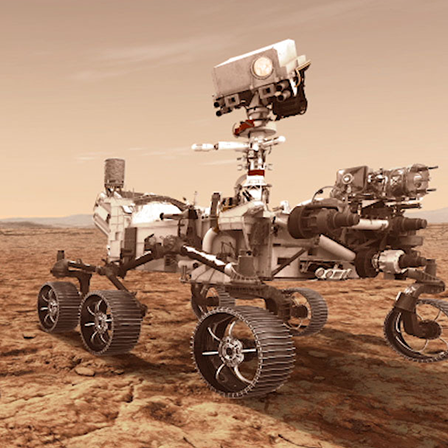

Fueled by technologies developed at Oak Ridge National Laboratory, the Perseverance rover is exploring Mars, assessing the planet’s habitability and looking for signs of microbial life.

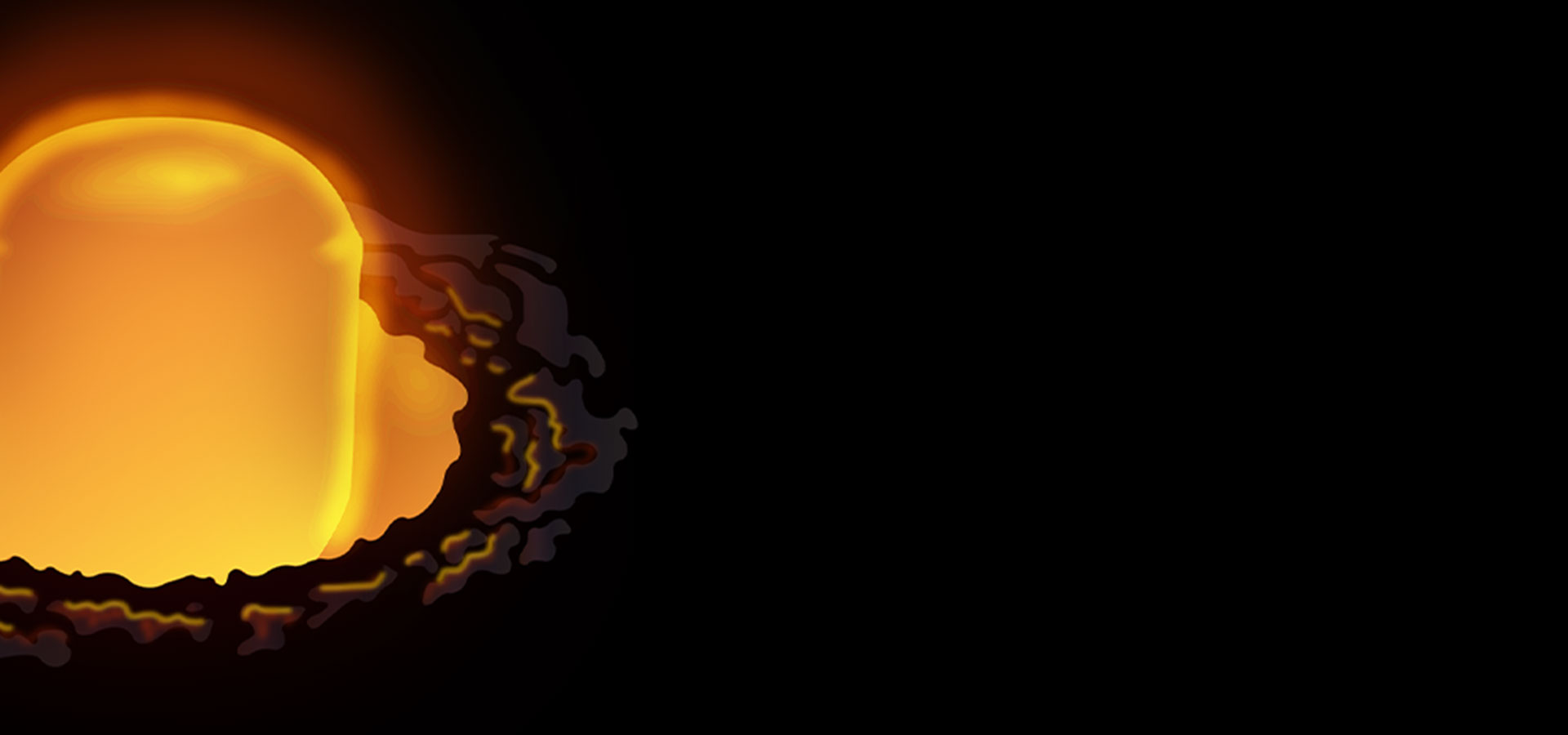

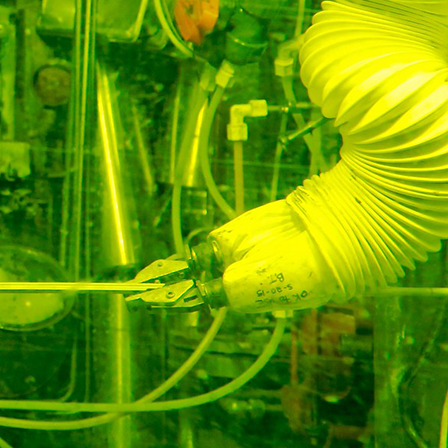

Plutonium-238 — encased in iridium-alloy cladding and insulated by carbon-bonded carbon fiber — is at the heart of the general purpose heat source module that fuels Perseverance’s multi-mission radioisotope thermoelectric generator. As the material decays, the heat released is converted to electricity, charging the rover’s batteries and powering the onboard advanced imaging and sensor systems.

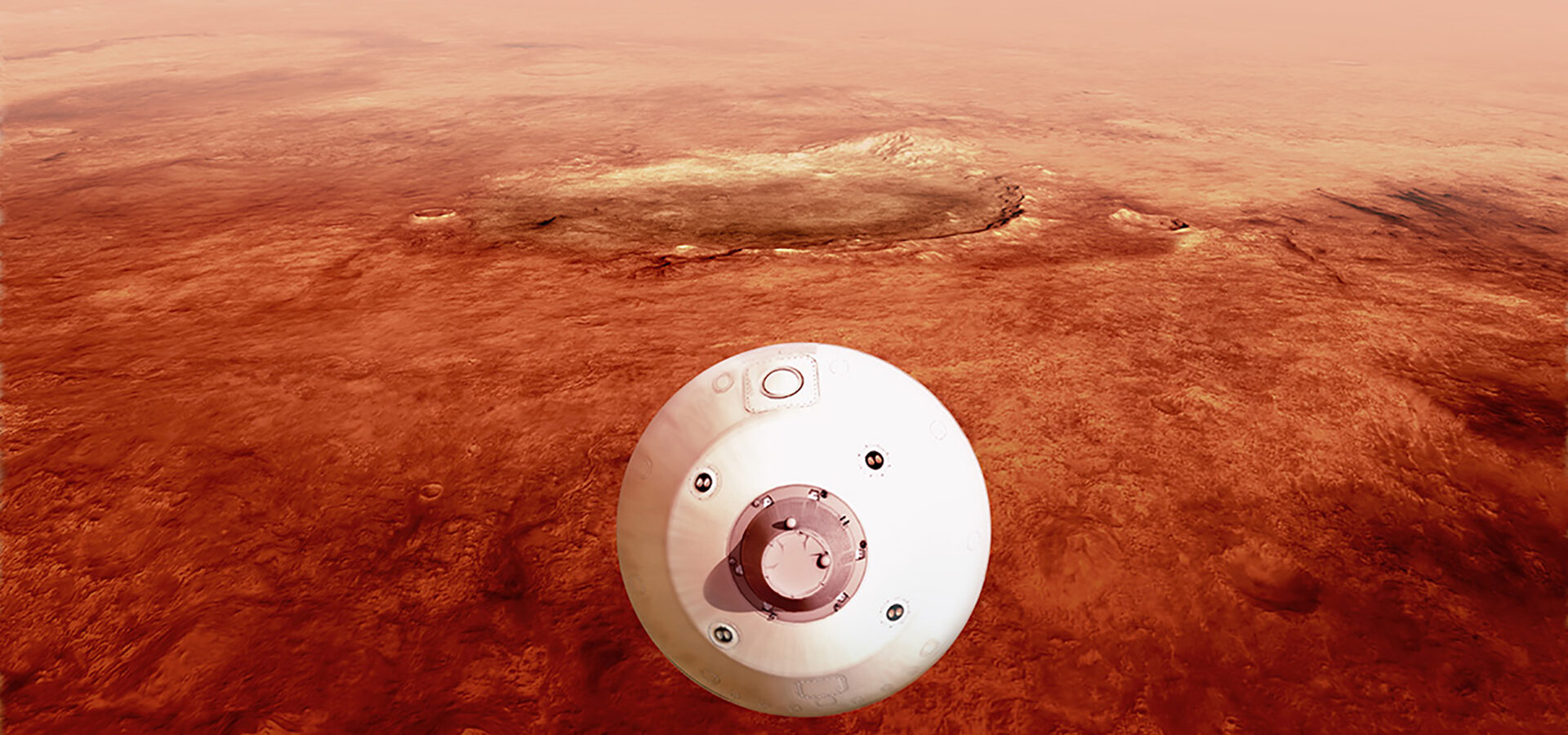

NASA’s Mars 2020 mission launched from Cape Canaveral, Florida, on July 30, 2020. After a seven-month journey to the Red Planet, the Perseverance rover landed in Jezero Crater on February 18, 2021.

The mission continues a 50-year legacy of the lab’s contributions to deep-space exploration, including technologies for the Voyager I and II, Cassini, and Mars Curiosity missions. ORNL-produced Pu-238 also will power NASA’s 2027 Dragonfly mission to explore Titan, Saturn’s largest moon.